APO PWIS-free cleaning

PERFECT CLEANLINESS

In coating processes, particular attention must be paid to the cleanliness of all components. Contamination that interferes with uniform coating application must be consistently removed. The coatings themselves, the parts to be coated and all components of the coating supply system and the entire coating operation must be free of substances that can impair the wetting properties of the coating. These cleanliness requirements are often described as PWIS-free, grease and oil-free, silicone-free or PWIS-compliant.

With our individually customised PWIS-free cleaning, we ensure that you can confidently apply coating technology to your components.

WHAT IS PWIS AND WHAT IS PWIS-FREE?

In order to clarify the question of what PWIS-free means, it is first of all important to know what the term PWIS means, where the PWIS-free definition comes from and what problems so-called PWIS can cause.

PWIS is the abbreviation for the term “paint wetting impairment substances”. This comes from coating technology and describes all those substances that, when coating surfaces, lead to certain defects, so-called craters, in the applied coating. The term “paint wetting impairment” describes the damage process very precisely.

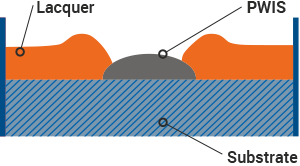

During a liquid lacquer application, if the wetting of the surfaces with the liquid lacquer is hindered by PWIS, the lacquer does not form a continuous film. This results in imperfections and holes in the coating layer, the craters.

HOW DOES PAINT WETTING IMPAIRMENT OCCUR?

Complete wetting with lacquer requires that its surface tension is lower than that of the surface being coated: 𝝈 Lack < 𝝈 Substrat

If it is not, as in the case of PWIS-contaminated areas, the lacquer withdraws from the substrate at the corresponding points: 𝝈 Lack > 𝝈 LABS

PWIS-contaminated surfaces cannot therefore be wetted or can only be partially wetted by the lacquer.

HOW DOES A PRODUCT BECOME PWIS-FREE OR PWIS-COMPLIANT? – THE CLEANING

Unless a product has been specially manufactured from PWIS-compliant materials and external contamination has been avoided during the manufacturing process, components generally need to be cleaned. Different cleaning methods are used depending on the material and size of the components. Car bodies, for example, are also cleaned with solvents, among other things.

However, in the case of polymer materials, especially elastomers, solvents can often only be used with caution or not at all due to the sensitivity of the materials. Also, from an environmental protection point of view, other, far more efficient cleaning processes are available. In such cases, it makes sense to use combined cleaning processes:

Firstly, water-based wet chemical (pre-)cleaning is carried out to remove stronger layers of dirt and inorganic contamination. This is followed by plasma cleaning to remove any remaining very thin residues of organic substances and to eliminate critical softening agents and other substances from the upper layers of the material.

We at APO GmbH are at home in the world of coatings and will be happy to advise you in detail on cleaning and testing options for clean solutions for your small components. Please contact us!

PWIS-FREE CLEANING

THE CHALLENGE

All components, regardless of their number, size and characteristics, must not only be PWIS-compliant at the start of their use, but must also not release any substances that could impair wetting of the coating over the entire period of use. The cleaning of elastomer components, such as seals, is therefore particularly demanding. Elastomers often contain substances that can have an effect on wetting by coatings. For this reason, elastomer components in particular should not be used in lacquer processing production areas without prior, thorough PWIS-free cleaning.

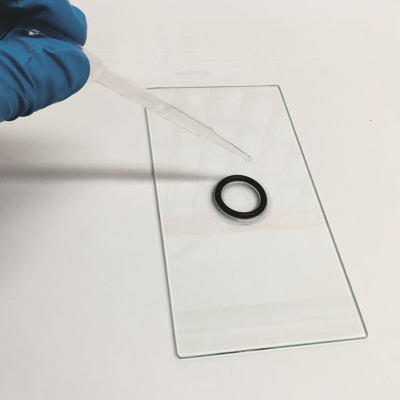

Small components, such as O-rings or other sealing elements, must also be treated with the utmost care.

ELASTOMERS ARE PWIS CRITICAL

Some chemical substances, such as softening agents or anti-ageing agents, can leak or ooze out of the materials over time and migrate to the surfaces. They are deposited there and can transfer to the coating system, the substrate or the lacquer and impair the coating. The release agents used in the production of polymer components must also be viewed critically. These facilitate the demoulding of components during mould-based production using injection moulding or compression processes, but are deposited on their surfaces.

Cleaning must therefore have an intensive effect on the surface and get deep into the material in advance to remove substances that can dissolve from the inside of the materials.

THE SOLUTION

APO’s PWIS-free cleaning process, a combination of wet-chemical processes and low-pressure plasma, can be customised to your requirements, the material and the degree of contamination of the components.

Components cleaned in this way meet the requirements of various test specifications for PWIS-free or PWIS-compliant products, such as VDMA 24364 or the VW specification PV.3.10.7.

LABS-FREI REINIGUNG

DIE HERAUSFORDERUNG

Alle Bauteile, unabhängig von Anzahl, Größe und Beschaffenheit, müssen nicht nur zu Beginn ihres Einsatzes LABS-konform sein, sondern dürfen auch über den gesamten Einsatzzeitraum hinweg keine lackbenetzungsstörenden Substanzen abgeben. Vor allem die Reinigung von Elastomerbauteilen, wie beispielsweise Dichtungen, gestaltet sich daher besonders anspruchsvoll. Elastomere enthalten oft Substanzen, die lackbenetzungsstörend wirken können. Daher sollten insbesondere Elastomer Komponenten nicht ohne eine vorherige, tiefgreifende LABS-frei Reinigung in lackverarbeitenden Produktionsbereichen eingesetzt werden.

Auch auf die kleinen Komponenten, wie O-Ringe oder andere Dichtelemente muss also unbedingt geachtet werden.

ELASTOMERE SIND LABS KRITISCH

Einige Inhaltsstoffe, wie Weichmacher oder Alterungsschutzmittel, können sich über den Lauf der Zeit aus den Werkstoffen austreten bzw. ausschwitzen und an die Oberflächen migrieren. Dort lagern sie sich ab und können auf das Lacksystem, das Substrat oder den Lack übergehen und die Lackierung beeinträchtigen. Daneben sind auch die bei der Herstellung von Polymerbauteilen eingesetzten Trennmittel kritisch zu betrachten. Diese erleichtern bei der formgebundenen Produktion im Spritzguss- oder Pressverfahren das Entformen der Bauteile, lagern sich aber auf deren Oberflächen ab. Eine Reinigung muss daher intensiv an der Oberfläche wirken und tief in den Werkstoff gelangen, um Substanzen, die sich aus dem Inneren der Werkstoffe lösen können, vorab zu entfernen.

DIE LÖSUNG

Der LABS-frei Reinigungsprozess von APO, eine Kombination aus nasschemischen Prozessen und Niederdruck-Plasma, lässt sich individuell auf Ihre Ansprüche, auf den Werkstoff und den Verschmutzungsgrad der Bauteile anpassen. Auf diese Weise gereinigte Bauteile erfüllen die Anforderungen unterschiedlicher Prüfspezifikationen zur LABS-Freiheit bzw. LABS-Konformität von Produkten, wie zum Beispiel nach VDMA 24364 oder der VW Spezifikation PV.3.10.7.

Mehr Details zu unserer Vorgehensweise bei der LABS-frei Reinigung

YOUR ADVANTAGES

Customised cleaning solutions make it possible to efficiently obtain the desired PWIS cleanliness results and pass the necessary PWIS tests.

The use of special cleaning technologies offers potential savings in terms of time and costs.

No unnoticed introduction of paint wetting impairment substances into coating facilities due to residues on or in components.

SILICONE-FREE, PWIS-FREE OR PWIS-COMPLIANT? – THE RIGHT DEFINITION

For the safe use of components or materials in a coating operation, it is important to define the necessary PWIS cleanliness and nature of the products in a meaningful way and to check them accordingly. Numerous definitions and test specifications are available to suppliers. But which definition makes sense and how can it be checked?

The properties of components or materials that can be used without hesitation in coating processes are often referred to as PWIS-free, silicone-free, grease and oil-free or PWIS-compliant. What do these definitions mean and which is the correct one?

DEFINITION OF PWIS REQUIREMENTS

Silicone-free is arguably the oldest description of the required cleanliness for products intended for use in coating fields. In the past, it was mainly silicones that attracted attention as paint wetting impairment substances, so even today the term silicone-free is still often used erroneously. In addition to silicones, however, there are many other substances that can interfere with wetting by coatings.

The same applies to the definition of grease and oil-free. There are many paint wetting impairment substances that cannot be categorised as either greases or oils. And there are also greases and oils that do not impair paint wetting at all.

PWIS-free is also a very frequently requested product property to describe the necessary cleanliness or properties and also falls short of the requirements. The sources of paint wetting impairment substances are very diverse. From softening agents in plastics, through release agent residues, to production materials or personal care products. A negative list of PWIS does not exist. Whether a substance has a paint wetting impairment effect depends on its interaction with the coating system, the substrate and the ambient conditions. It is therefore not possible to say that a product is generally PWIS-free.

The term PWIS-compliant was coined in VDMA Standard Sheet 24364, a specification for testing products for paint wetting impairment substances. PWIS-compliant describes much more precisely the properties that are really necessary for components in coating processes. This definition takes into account both the places of use in the coating process, the sensitivity to PWIS – the so-called PWIS relevance – and the operating conditions of the products.