Coatings and PFAS

PERFLUORINATED AND POLYFLUORINATED ALKYL SUBSTANCES IN BONDED COATINGS

Since the beginning of 2023, many customers have been speaking to us about PFAS. The reason for this is the general REACh restriction proposal for perfluoroalkyl and polyfluoroalkyl substances, or PFAS, published by the ECHA (European Chemicals Agency) in February 2023. Since then, many customers have been concerned that some coatings will soon no longer be available due to the planned restrictions.

Here we explain why PFAS restrictions are being discussed and to what extent coatings are affected:

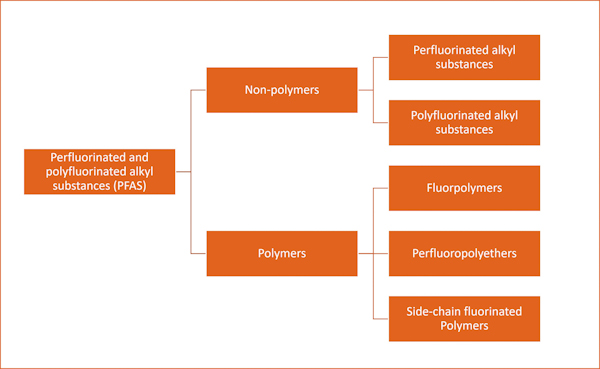

WHAT ARE PFAS?

PFAS are perfluorinated and polyfluorinated alkyl substances. These are organic compounds in which hydrogen atoms are either completely (“perfluorinated”) or partially (“polyfluorinated”) replaced by fluorine atoms. The resultant carbon-fluorine bonds are among the most stable bonds in organic chemistry. PFAS therefore exhibit particularly valuable properties from a technical point of view. They are thermally and chemically very stable and repel water, dirt and grease. More than 4,700 different substances (source: EEA – European Environment Agency), including many important industrial chemicals, are PFAS.

WHAT RISKS ARE PRESENTED BY PFAS?

Not all PFAS are equally risky for human health and the environment. The hazard posed by a substance depends on its chemical structure. PFAS are considered to be persistent, i.e. they remain in the environment for a very long time without being broken down, which is why they are also known as “forever chemicals”. In addition, some can be spread over long distances or accumulate via the food chain (bioaccumulation) and thus enter the human organism. Some individual compounds are considered toxic.

WHY SHOULD PFAS BE RESTRICTED?

According to the EEA (European Environmental Agency), some PFAS can lead to health problems such as liver damage, thyroid disorders, obesity, fertility problems or cancer. The stated aim is therefore to restrict the use of PFAS and the introduction and circulation of products containing PFAS in the EU as far as possible in order to protect the environment and people from short and long-term consequences. At this point in time, no one knows which fluorinated alkyl substances will ultimately be affected by restrictions and to what extent (as of December 2023).

ARE COATINGS AFFECTED BY THE PROPOSED PFAS RESTRICTIONS?

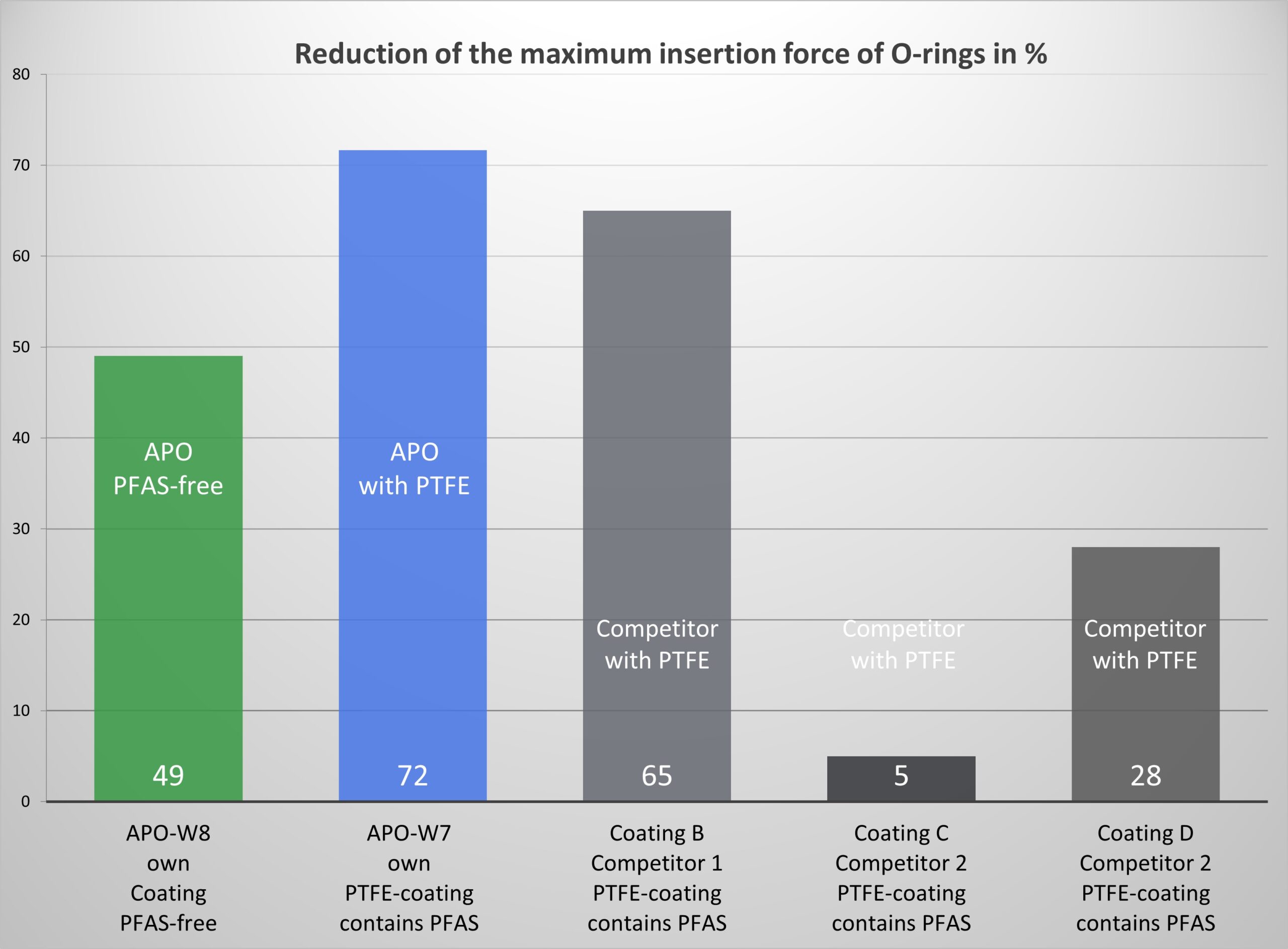

In fact, all coating systems that contain PTFE belong to the PFAS group. This is because polytetrafluoroethylene (PTFE) is a polymer of fluorine and carbon. Should PTFE materials be affected by restrictions, these will also affect the coating sector. So much for the facts, everything else remains speculation at the moment. Nevertheless, as a partner for coating solutions, we have already reacted and developed new bonded coatings without PFAS. You are therefore welcome to contact us about our PFAS-free coatings or take a look at the following information.

THE SOLUTION

PFAS-free High-Performance coatings

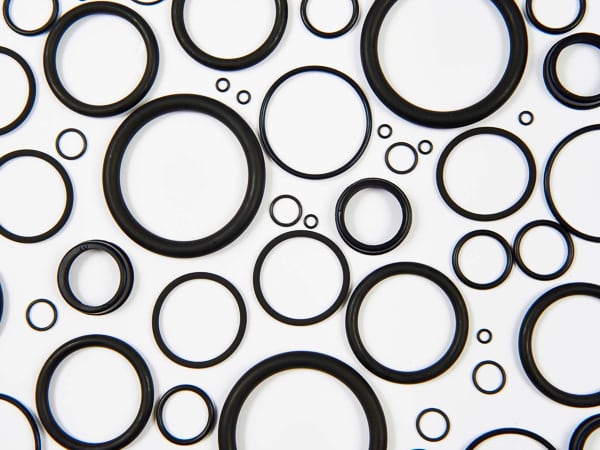

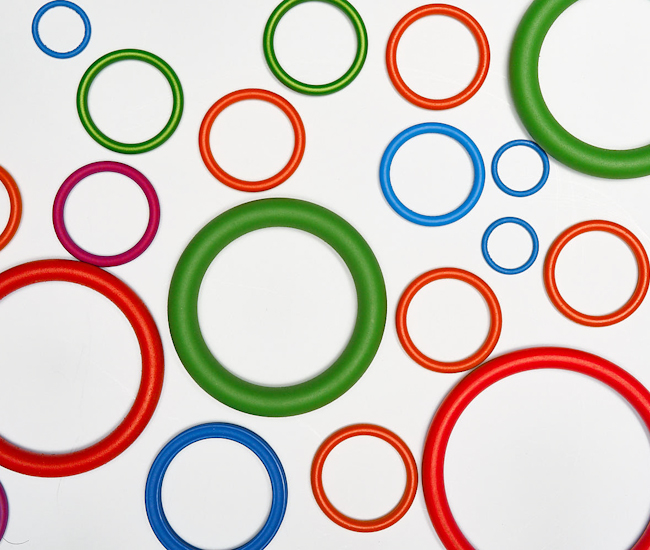

Our PFAS-free coating solutions offer the best possible replacement for current PTFE coatings. They improve the friction properties of small technical plastic and elastomer parts, facilitate assembly and prevent stick-slip effects.

PFAS-FREE COATINGS – USE AND ADVANTAGES

Our PFAS-free coatings can be applied to many different materials and components. They adhere firmly to the component surfaces and yet are highly elastic. They improve the friction properties of plastic and elastomer parts, facilitate their assembly and protect the components from damage during installation. In addition, they permanently reduce the frictional forces and abrasion of elastomer parts in dynamic use and ensure low starting resitances after prolonged periods of inactivity. The coatings also effectively counter so-called stick-slip effects and prevent seals from sticking to their contact surfaces.

The advantages at a glance:

- Clean dry lubrication to facilitate assembly and insertion processes

- Permanent anti-friction layer to reduce stick-slip and friction in dynamic applications and starting resistances after periods of inactivity

PFAS-FREE COATINGS – BENEFITS

With our PFAS-free bonded coating, elastomer and plastic components exhibit particularly favourable surface properties. The highly elastic layers protect the components and facilitate their use and handling in technical applications:

- Time savings through trouble-free processes

- Force reductions of up to 50 % during insertion and assembly processes, depending on the component and installation situation

- Protection against damage to components during installation

- Low frictional forces in dynamic use

- Extended component service life due to greater assembly reliability and reduced abrasion

- More security in valve seals thanks to protection against elastomer seals sticking together

PFAS-FREE COATINGS – PERFORMANCE PROFILE

With an application temperature range of -40 °C to 150 °C, our PFAS-free coatings are suitable for common technical applications in which elastomer parts are used, for example in sealing technology.

As elastomer parts are often stretched during assembly, the coating provides the appropriate elasticity. Provided that the prerequisites for optimum surface adhesion to the base part are fulfilled, it can withstand elongation of up to 100 per cent, ohne zu reißen, sich aufzuwerfen oder von der Bauteiloberfläche abzulösen. Our PFAS-free coating offers broad media resistance for use in various sealing applications. The chemical resistance of the bonded coating was tested in various test media commonly used in elastomer technology using recognised test methods.

Our PFAS-free coatings are available either in a transparent version with UV indicator or in colours to match your individual requirements.