PWIS background

THE HISTORY OF PAINT WETTING IMPAIRMENT

The phenomenon of paint wetting impairment is largely related to the wet paint system used, i.e. the type of paint. There have been a number of developments in the past that have led to an intensification of the basic problem of paint wetting disorders.

CAR PAINTS – FROM THE BEGINNING TO TODAY

The first automotive paints at the beginning of the twentieth century were manufactured from natural ingredients. These were replaced by oil-soluble automotive paints around 1910. In the following years, the development of automotive paints continued due to the higher output in automobile manufacturing in order to improve processing and durability and to shorten drying times.

Motor vehicle painting – Towards mass production

In the 80s and 90s, two-component paints made from acrylic resins, the binder, and isocyanate, the hardener, were primarily used to paint car bodies. These solvent-based paints are easy to process, durable and resistant to external influences such as UV radiation, fuels or acids.

Vehicle paints and the environment

However, the processing of large quantities of solvent-based paints releases large quantities of volatile organic compounds – harmful to humans and the environment. The European Directive 1999/13/EC on the limitation of emissions of volatile organic compounds, which came into force on 11 March 1999, increased the pressure on the industry to further develop paints. The path to water-based coatings. Further directives followed, including Directive 2004/42/EC (Decopaint Directive) in 2004 and 2010/75/EU and 2010/79/EU on the limitation of VOCs (volatile organic compounds) in 2010. The prescribed limit values can now only be complied with by using water-soluble coating systems in spraying systems. Since then, water-soluble coating systems have been used primarily for car paintwork.

WATER-BASED COATINGS – THE DISADVANTAGES

Although VOC emissions have been reduced by the introduction and further development of water-based coatings, this change in coating technology has brought with it a number of drawbacks. For example, water-based coatings dry more slowly than the previous, highly solvent-based lacquers. This generally requires a higher heating requirement and therefore higher energy consumption during the drying phase.

However, the problem of paint wetting impairment in particular has been increased by the introduction of water-based coatings. Due to the low proportion of volatile solvents, water-based coatings can only absorb and dissolve impurities on the bodywork or other surfaces to a moderate extent. Water-based coatings therefore react more sensitively to all contaminants, which can impair uniform wetting with the liquid coating due to their low surface tension.

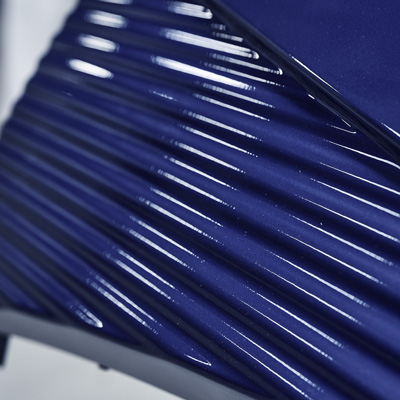

CRATERS IN THE COATING DUE TO PAINT WETTING IMPAIRMENT

If the coatings, equipment or surfaces to be coated, such as car bodies, become contaminated with PWIS (paint-wetting impairment substances), the liquid coating cannot form a continuous layer when sprayed on. In the contaminated areas, the coating withdraws from the substrate, leaving imperfections, the so-called craters. The main cause of this withdrawal of the coating is the lower surface tension of the contaminating substance (PWIS) compared to that of the coating. It is therefore necessary to ensure that all components, substances and the entire coating process are kept clean.

good